A lot has been said about building semiconductor manufacturing plants in the US. One plant grows the silicon wafers and the other plant fabricates (fabs) the semiconductors. The manufacture of semiconductors is not labor intensive. Growing wafers is boring business as one engineer told me a decade back. The US did manufacture much of its need domestically at one time (see graph at the left). However, U.S. policymakers held tight to the belief it doesn’t matter who makes what where and trusted “comparative advantage” to leave each country specializing where it could naturally excel, foreign governments placed big bets on the value of dominating the digital future. One infamous remark was made by the chair of George H. W. Bush’s Council of

Topics:

run75441 considers the following as important: Dean Baker, Education, mRNA, politics, semiconductors, US EConomics

This could be interesting, too:

Robert Skidelsky writes Lord Skidelsky to ask His Majesty’s Government what is their policy with regard to the Ukraine war following the new policy of the government of the United States of America.

NewDealdemocrat writes JOLTS revisions from Yesterday’s Report

Joel Eissenberg writes No Invading Allies Act

Ken Melvin writes A Developed Taste

A lot has been said about building semiconductor manufacturing plants in the US. One plant grows the silicon wafers and the other plant fabricates (fabs) the semiconductors. The manufacture of semiconductors is not labor intensive. Growing wafers is boring business as one engineer told me a decade back.

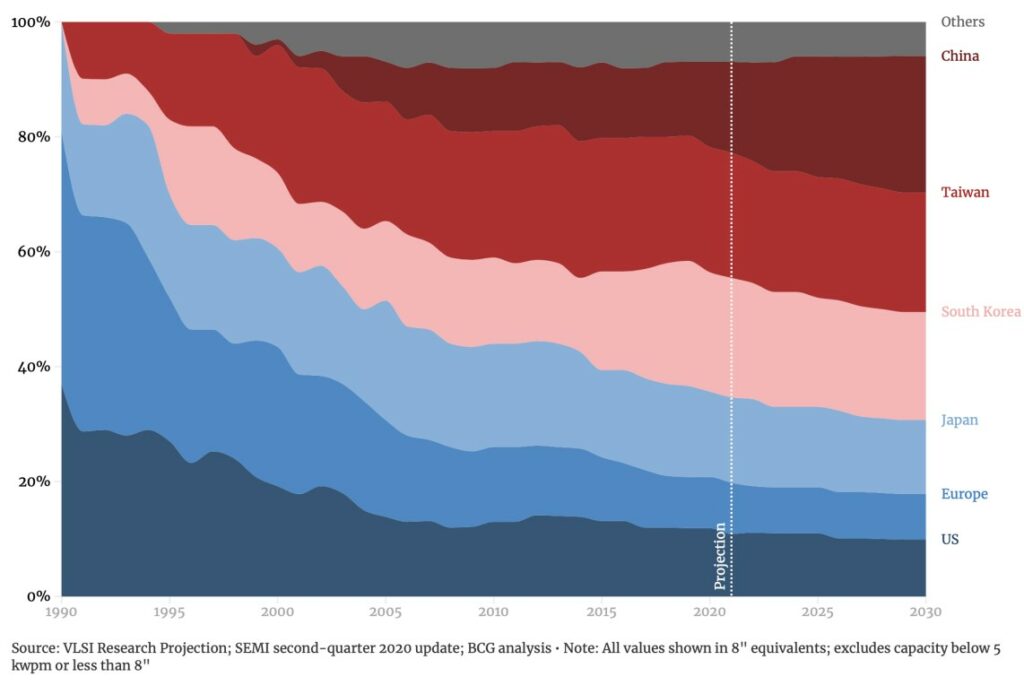

The US did manufacture much of its need domestically at one time (see graph at the left). However, U.S. policymakers held tight to the belief it doesn’t matter who makes what where and trusted “comparative advantage” to leave each country specializing where it could naturally excel, foreign governments placed big bets on the value of dominating the digital future.

One infamous remark was made by the chair of George H. W. Bush’s Council of Economic Advisors:

“Potato chips, computer chips, what’s the difference?”

I guess we found out how different electronic chips are from potato chips. $Billions will be spent in the US to resource manufacturing of an electronic component which has become essential to our economy and safety. It is a failure of modern economics to understand the importance of where your food, energy, and other essentials we dependent upon is sourced. I also guess where semiconductors are made is important as President Biden has signed the Chips and Science Act to support domestic manufacturing. It has become more of a national security issue as much of the semiconductor manufacturing is done in Taiwan. China believes Taiwan is part of China.

“The Semiconductor Bill and the Moderna Billionaires,” Center for Economic and Policy Research (cepr.net), Dean Baker

It’s pretty funny that we continually debate the causes of inequality when we routinely pass bills redistributing income upward. The semiconductor bill about to be approved by Congress is the latest episode in this absurd charade.

To be clear, the bill does some good things. It has funding both to subsidize manufacturing capacity for semiconductors in the United States. It also funds more research in developing better chips in the future. Both of these are positive developments even if the benefits of the former are overstated.

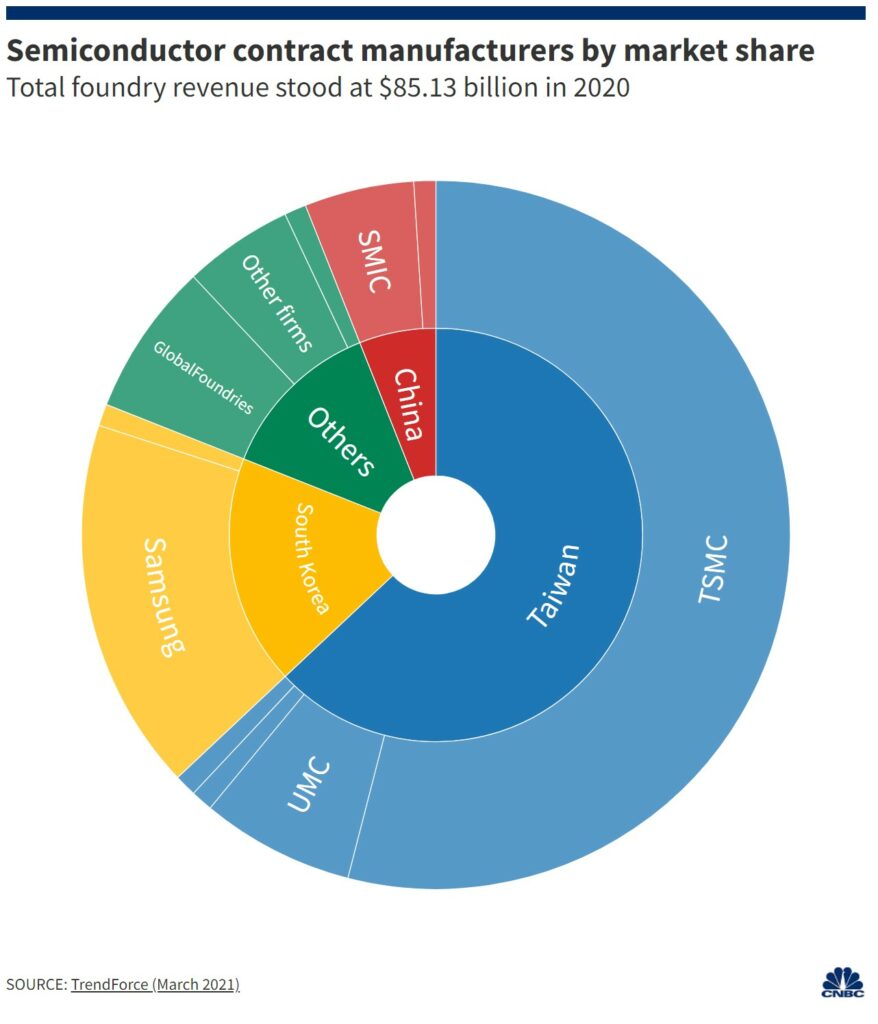

I added the image to the left. Click on the image to enlarge. Eighty-eight percent of the semiconductor business is manufactured in three countries, Taiwan (65%), Korea (18%), and China (5%). For the time being and working through ASML, “China’s SMIC has been cut off by the US from acquiring cutting-edge equipment it needs from the Dutch Company ASML. ASML makes the extreme ultraviolet lithography equipment that’s used to produce the most advanced chips such as those manufactured by TSMC and Samsung. It is here, I believe the US will build a plant to manufacture advanced semiconductors.

What they are doing is getting more transistors in a semiconductor by packing them closer (<10) together.

The ASML machine uses extreme ultraviolet (EUV) light beams, generated by lasers and focused by giant mirrors, to lay out extraordinarily narrow circuits on of silicon wafers which are grown in other facilities and sent to fab facilities. The newer technology it possible to create faster and more powerful microprocessors, memory chips and other advanced components, which are critical for consumer electronics and military applications alike. Korea’s Samsung and Taiwan TSMC have this capability.

Back to Dean Baker

It was common in the pandemic days to tout the supply chain problems as evidence that we needed more manufacturing in the United States in a variety of areas. However, the story ignores several factors.

First, the pandemic knocked out many factories in the United States also, it wasn’t just factories in Thailand and China that closed. Second, some of the problems were associated with shortages of truck drivers and other transportation workers and facilities. We need to transport goods made in the United States also, most people can’t just drive to the local furniture factory to pick up a new living room sofa.

Most importantly, the complaint about foreign sourcing ignores the fact we saw a massive increase in goods imports, as there was a huge pandemic-induced shift in consumption from services to goods. Real imports of goods increased by more than $270 billion from the fourth quarter of 2019 to the second quarter of 2021.

That is almost 1.5 percent of GDP. It is difficult to envision a scenario where we could increase domestic production of manufactured goods by anything close to that amount in the middle of a pandemic. In short, our supply chains actually served us pretty well in providing us with a lot more imported stuff as large parts of the domestic economy were shut down, even if there were shortages of many items, pushing prices higher.

The other misleading aspect of the virtues of this bill is the idea that the working class (noncollege educated workers) will benefit from more manufacturing jobs in the United States. While this would have been true 30 years ago, it is no longer true today. Thanks to our trade policies over this period, the wage premium in manufacturing has largely disappeared.

The manufacture of wafers for semiconductors (or slabs) is not labor intense. Simply, one plant is growing the silicon disks or slabs, These are sent to the Fab plant, cut, populated with transistors, and layered. Neither is Fab labor intensive. This does not mean other product can not return to the US for production. The issue is, does US manufacturers now want to pay higher labor costs in Overhead?

At the most basic level, the average hourly earnings of production and nonsupervisory workers in manufacturing is now less than 92.0 percent of the average for the private sector as a whole. A fuller comparison has to include nonwage (Overhead) compensation and also look at the specific demographics of manufacturing workers compared to the workforce as a whole. This could still leave some premium, but almost certainly a very small one.

The disappearance of the manufacturing wage premium has been associated with the closing of the gap in unionization rates between manufacturing and the private sector as a whole. In 1993, 19.2 percent of manufacturing workers were in unions compared to 11.6 percent for the private sector as whole. By 2021 the gap in unionization rates had been hugely reduced, with 7.7 percent of manufacturing workers being unionized, compared to 6.1 percent for the private sector as whole.

In this context, the increase in manufacturing jobs that might result from this bill is not likely to be any great boon for noncollege educated workers. There is little reason to believe that the manufacturing jobs created by this bill will be qualitatively better than the alternative jobs these workers might be holding.

To be clear, it is probably best to have more diverse sources for such an important input in the modern economy, so an increase in domestic capacity is desirable. And, being so dependent on sources that could be closed off in a confrontation with China is a problem, although the idea of pushing forward with a new Cold War with China is almost certain to prove disastrous for the United States and the world.

Subsidies for Research and Inequality

The other part of this bill is a substantial boost to research funding that will be focused on developing new generations of semiconductors and related technologies. This is positive in the sense that we would benefit from more research in these areas. However, the problem is that the gains from developments in these areas will go disproportionately to those already at the top of the income ladder.

The development of the mRNA technologies and Moderna are the case study here. The development of mRNA technology over the last four decades was largely on the public dime, mostly through grants from the National Institutes of Health. Moderna recently began its own research, although it had not yet brought a successful vaccine to the market at the time the pandemic began.

The federal government paid Moderna $450 million dollars to develop its vaccine against the coronavirus. It then paid roughly the same amount for Moderna to conduct clinical trials to demonstrate its effectiveness.

It then let Moderna keep ownership of the intellectual property it had developed while working for the government. In effect, the government paid Moderna twice, once with the public funding, the second time by giving them monopoly control over what they developed.

As a result, according to Forbes, we had created at least five Moderna billionaires as of last summer. Undoubtedly many other well-placed people in the company pocketed tens or hundreds of millions. While the origins of rising inequality may be a mystery to many economists, it really shouldn’t be very surprising to anyone who follows the news.

We will spend over $500 billion on prescription drugs this year. If we did not give out patent monopolies or related protections the cost would almost certainly be less than $100 billion. The difference of more than $400 billion a year comes to roughly $3,000 a family or more than half of the military budget.

If we actually want to promote technology in a way that doesn’t hugely increase inequality we can use a system that only pays companies once. We can make it a condition of the funding that all the products developed have short patents. I proposed four years as a general rule, with everything in the public domain immediately in the case of biomedical research and climate. (See chapter five of Rigged [it’s free].)

If US companies find these terms too onerous, there are sure to be plenty of researchers elsewhere in the world happy to take our research dollars on these terms. Remember, we shouldn’t care at all where the researchers are located, the research will be open and available for our manufacturers here, as well as elsewhere, as a condition of the contracts. It is what economists and policy types always hype: free trade.

We Can Support the Economy Without Redistributing Upward

In short, with a bit of thought, the semiconductor bill could have been designed in ways that did not redistribute income upward. We need to get over the idea that manufacturing jobs are a fix for the problems of noncollege educated workers. That was true 30 years ago when our political leaders were vigorously pushing policies to destroy these jobs. However, thanks to their success in these efforts, bringing the jobs back won’t fix the problem.

The other point is that it is not technology that gives lots of money to those with skills in STEM and other areas, it is our policies on technology. As long as we can’t have a serious policy debate on altering these policies, we will continue to see further upward redistribution. It is that simple.

“Chips bill advances to Biden’s desk — Here’s what’s in the soon-to-be law” (yahoo.com)

“Union Members in 1993,” BLS.Gov

“Union affiliation of employed wage and salary workers by occupation and industry,” BLS.Gov

“AC-Atlas-Semiconductors_Final.pdf” (americancompass.org)