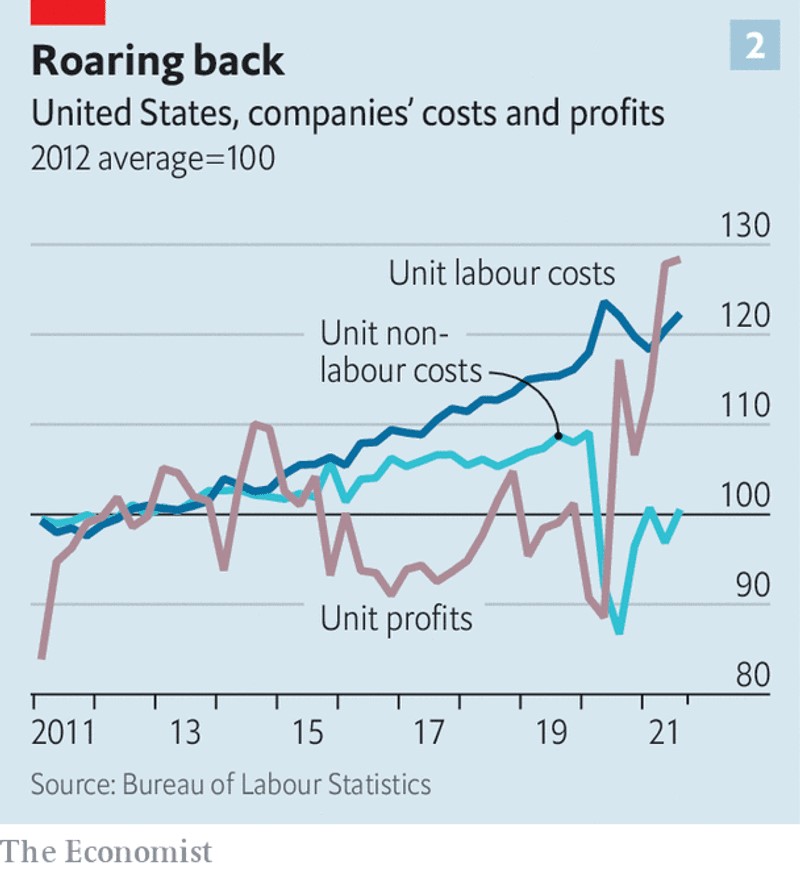

“Labour v capital in the post-lockdown economy,” The Economist. As prices and wages rise, are workers or firms winning? Pulling a brief article from The Economist. Unlike 2008, Labor is surviving due to stimulus packages in 2020/2021, which petered out in 2008 leaving low wages and restrictive Unemployment Benefits. “An economy-wide measure of corporate margins is rising fast. Dario Perkins of TS Lombard, a financial-services firm, breaks down America’s rise in unit prices since the start of the pandemic into companies’ labour costs, non-labour costs, and profits. Wages are rising, but nonetheless, markups are responsible for more than 70% of inflation since late 2019, he finds (see chart 2). In a recent report, analysts at Bank of America

Topics:

run75441 considers the following as important: Hot Topics, politics, The Economist, US/Global Economics

This could be interesting, too:

Robert Skidelsky writes Lord Skidelsky to ask His Majesty’s Government what is their policy with regard to the Ukraine war following the new policy of the government of the United States of America.

NewDealdemocrat writes JOLTS revisions from Yesterday’s Report

Joel Eissenberg writes No Invading Allies Act

Ken Melvin writes A Developed Taste

“Labour v capital in the post-lockdown economy,” The Economist. As prices and wages rise, are workers or firms winning?

Pulling a brief article from The Economist. Unlike 2008, Labor is surviving due to stimulus packages in 2020/2021, which petered out in 2008 leaving low wages and restrictive Unemployment Benefits.

“An economy-wide measure of corporate margins is rising fast. Dario Perkins of TS Lombard, a financial-services firm, breaks down America’s rise in unit prices since the start of the pandemic into companies’ labour costs, non-labour costs, and profits. Wages are rising, but nonetheless, markups are responsible for more than 70% of inflation since late 2019, he finds (see chart 2). In a recent report, analysts at Bank of America argue that greater pricing power helps explain why American equities have a higher price-earnings ratio than European.

The thought here is longer lead times and increased pricing will slow or decrease demand. Indeed, the lengthening of lead times does nothing to impede demand. More people get in line for company products or companies just throw another order on top of the orders they have in place already. This is what occurred in 2008-10 with semi-conductor orders.

Funny, how companies have the same 5 to 6 month lead time for product. It then shows up in half the lead time.

If demand is real, which it appears to be, there should not be a cost increase unless companies are going to overtime or using older capacity which is less efficient. Even so, Labor would be the smaller of the costs. It appears companies are taking advantage of an opportunity to slip in more profit-taking during a pandemic.

Evidence of the profit-taking is shown in the graph. Labor costs are up but they represent a small portion of the total cost. The rest of the costs or Overhead are up. And the governor of the Bank of England wants to whack Labor the same as every Fed has done since Volcker.

The stimulus packages are decreasing or gone by now having done what they should do. The extended healthcare benefits will also dissipate and as well the child tax credits direct funds to families. It is unfortunate, we do not have a Senate which would keep the child tax credits (Joe Manchin), extend healthcare benefits which were also part of the bill and benefited West Virginia greatly.

Silly – me, what was this old manufacturing consultant thinking?

I was consulting in Piqua, Ohio at a tubing manufacturer. The issue was how to speed up the extrusion process to improve lead times. Not a difficult task . . . if they listen. They were running Lots (set quantities) through the mandrels. The first thing out of my mouth to improve delivery was to cut Lot sizes. “Oh, we can not justify mandrel setups then.” Improve setup times. Create handles to tighten tooling down, make tooling resident to the mandrels, move inventory closer, etc. All Lean Manufacturing stuff. I think I was on a different planet. The VP was angry at me.

The above would have moved the material quicker with less sit-around time at the other stations down the line. I pulled their labor time at each operation, along with processing time, and the time to move material (calculation) from one operation to another. Made my little pie charts showing three portions, the smallest of which was actual Labor (manufacturing) time and the largest being sit-around time at each operation. The VP said to me, I thought we had this conversation. I explained to him, this was his data.

He sat down and was quiet.

The company’s inventory of coils of steel in their warehouse looked like the scene from Aliens where they are looking at an array of the Alien’s eggs.

My point to this story (actual) is things do not seem to be what they really are at times. Companies can and will use unsupported excuses or just plain ignorance to justify their actions. This is why we shouldn’t whack Labor to fix a supply and throughput issue being used to justify higher prices-profits.

It applies to food and gasoline too.