Following up Joel Eissenberg’s commentary “Is 3D printing the answer to the housing crisis?” with some history on prefabs as supplied by Lloyd Alter of Carbon Upfront. A bonus from the archives, looking at the work of Carl Koch. by Lloyd Alter Carbon Upfront! There has been so much news recently about how prefab could finally revolutionize housing. The Canadian government in particular has suggested that Prefabricated housing offers one solution to the supply crisis. Architects have been saying it for years; when a major prefab company went bust in 2008 I wrote a post, now deleted, about how long people have been saying prefab is the future of housing.. I found it in the Wayback Machine and republish it here: While writing the obit

Topics:

Angry Bear considers the following as important: Education, Prefab Homes

This could be interesting, too:

Joel Eissenberg writes The Trump/Vance Administration seeks academic mediocrity

Bill Haskell writes Study Shows Workers Fleeing States With Abortion Bans

Angry Bear writes The Impact of Debt Interest Payments

Angry Bear writes Rust Belt Cities reborn?

Following up Joel Eissenberg’s commentary “Is 3D printing the answer to the housing crisis?” with some history on prefabs as supplied by Lloyd Alter of Carbon Upfront.

A bonus from the archives, looking at the work of Carl Koch.

by Lloyd Alter

There has been so much news recently about how prefab could finally revolutionize housing. The Canadian government in particular has suggested that Prefabricated housing offers one solution to the supply crisis. Architects have been saying it for years; when a major prefab company went bust in 2008 I wrote a post, now deleted, about how long people have been saying prefab is the future of housing.. I found it in the Wayback Machine and republish it here:

While writing the obit for Empyrian Homes (formerly Deck Homes and Acorn Homes) I alluded to the original Acorn house, describing it briefly and noting that Acorn founder John Bemis put it together with Architect Carl Koch. I could find little information, other than references to a Life Magazine article and one reference to a book by Koch. Through the wonders of ABE I was able to find and buy a copy.

And what a remarkable story it tells, and how little things have changed in fifty years.Koch tells the story from the very beginning:

As to how it began: The idea of demountability is, of course, not new. The nomads of Asia have been at it for years, with houses of frame and hide- Yurts. Even before the second world war, there were a number of experiments with demountability or yurtdom . . .

At wars end I was stimulated to read about vast available amounts of surplus material. Aluminum, for instance…I began trying to bring the idea together with realities.

He began looking at stressed skins:

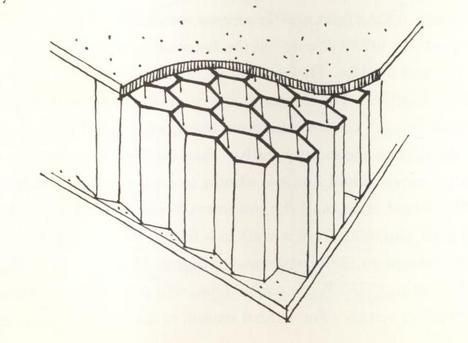

The Forest product laboratory has done a considerable amount of development work on [stressed skins.] IF you impregnate the paper honeycomb with plastic and glue it rigidly to a sheathing material you get what is known as a stressed-skin construction, which has strength and insulative ability out of all proportion to its weight and a theoretically very low cost.

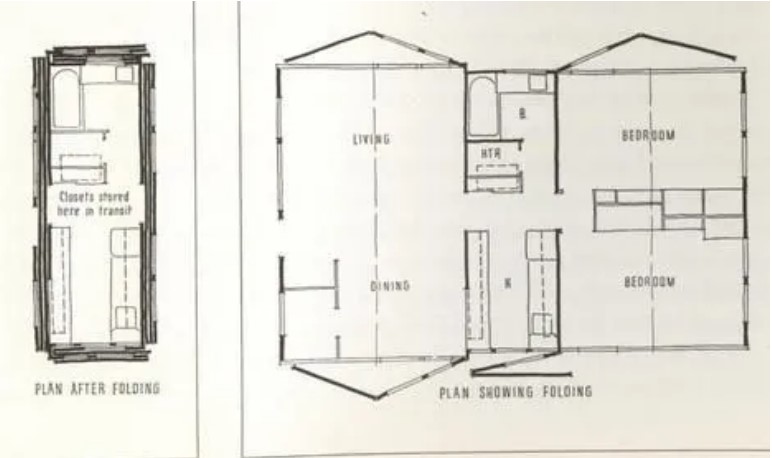

Then he designed the house, using a principle reinvented many times since, in Michelle Kaufmann’s Breeze house and others, where you build the core in three dimensions but the big rooms in flatpack.

Here, at any rate, was an estimable means of enclosing space- but how much space, of what shape, and how divided up? Here there was a handy necessity:

If the house were to be portable by truck, no section of it should exceed a width of eight feet. The question then was what part of the those might be designed, sawed, folded or otherwise compressed into eight foot widths and what might not?

It seemed reasonable that one such section, 8 by 24 feet, should comprise the core of the house: the kitchen, and bathroom, plumbing heating and the like. The reasons were several; For one thing, eight feet is a good width for a kitchen. For a second . . . the stringing of pipes to widely separated areas, and the innumerable, individual tasteful ways of hitching them up have raised plumbing from a craft to a fine, expensive art. For a third reason, to anticipate a point, it’s hard to fold a bathtub.

He then went off in search of surplus materials and thought the airplane companies might want to build the house- they needed something to do. They said SURE!

If the government would put up a few million dollars to get the thing started for them. After all, that is how they made planes- cost-plus and all that.

He went to the government- interest and promises but nothing practical or immediate.

The he went to the aluminum companies:

They weren’t just sure that they wanted to manufacture whole houses. But the research director of one of the largest companies was pinning his bright future hopes for housing on the making of doorknobs.

Finally he met John Bemis, an engineer and son of a pioneer builder, who decided that if no one else was going to build the house, then by gollies, he would.

They were not fond of the name Acorn, (Folding Homes and “Resin-dences” were considered) but stuck with it. That is when the trouble started. For it was not a conventional house.