By Lloyd Alter Carbon Upfront! The economist John Maynard Keynes purportedly said, “When the facts change, I change my mind. What do you do, sir?” I am considering changing my mind about 3D printed houses. I wrote eight years ago: “I am not a total skeptic about 3D-printed houses. I think there is a place for them—on the moon, for example.” The first commenter noted: “What a stupidly conservative view… the article is absolute garbage.” Perhaps he was right. Last year in this space I looked at a 3D printed subdivision in Texas, Homes at Wolf Ranch, built by ICON and the big developer Lennar, all “co-designed” by Bjarke Ingels Group. I was forced to admit then that this was looking promising, concluding, “perhaps I shouldn’t be such a

Topics:

Angry Bear considers the following as important: climate change, Lloyd Alter, US EConomics

This could be interesting, too:

NewDealdemocrat writes JOLTS revisions from Yesterday’s Report

Bill Haskell writes The North American Automobile Industry Waits for Trump and the Gov. to Act

Bill Haskell writes Families Struggle Paying for Child Care While Working

Joel Eissenberg writes Time for Senate Dems to stand up against Trump/Musk

by Lloyd Alter

Carbon Upfront!

The economist John Maynard Keynes purportedly said,

“When the facts change, I change my mind. What do you do, sir?”

I am considering changing my mind about 3D printed houses. I wrote eight years ago: “I am not a total skeptic about 3D-printed houses. I think there is a place for them—on the moon, for example.” The first commenter noted: “What a stupidly conservative view… the article is absolute garbage.”

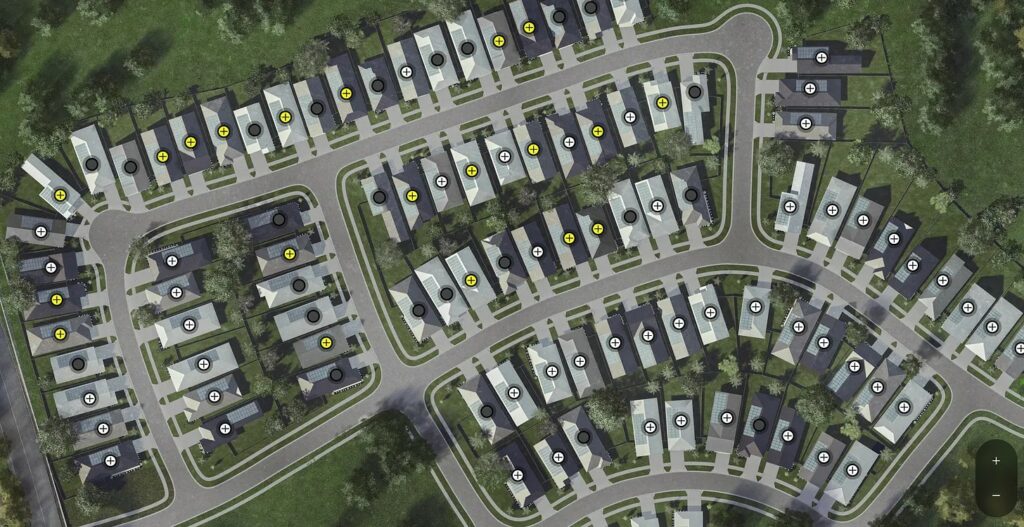

Perhaps he was right. Last year in this space I looked at a 3D printed subdivision in Texas, Homes at Wolf Ranch, built by ICON and the big developer Lennar, all “co-designed” by Bjarke Ingels Group. I was forced to admit then that this was looking promising, concluding, “perhaps I shouldn’t be such a stupidly conservative curmudgeon.” Now, according to Reuters, the subdivision is almost complete, and ICON touts the advantages:

“It brings a lot of efficiency to the trade market,” said ICON senior project manager Conner Jenkins. “So, where there were maybe five different crews coming in to build a wall system, we now have one crew and one robot.”

This is not exactly true; they have five robots, and it takes three weeks to print the walls of a one-storey house, which is not exactly fast. But they say, “compared to traditional construction, the company says that 3D printing homes is faster, less expensive, requires fewer workers, and minimizes construction material waste.”

There is also a huge capital investment here, compared to conventional construction, and they have to feed the machines. According to Reuters,

“Developers said a little more than one quarter of the 100 homes have been sold.”

This is not how subdivisions usually get built; conventionally, buyers get to pick their plans and then the house gets started. Someone is putting a lot of money upfront here and taking big risks; at $500K per house they are sitting on $37.5 million in inventory.

Now, let’s look on the bright side. These homes are solid, and really quiet. if the conventionally framed roofs are tied down properly, they will be resistant to water, mold, termites and extreme weather. One homeowner says “It feels like a fortress.” Apparently, the biggest problem they have is getting a good WIFI signal through the walls, with the homeowner telling Reuters:

“Obviously these are really strong, thick walls. And that’s what provides a lot of value for us as homeowners and keeps this thing really well-insulated in a Texas summer, but signal doesn’t transfer through these walls very well.”

The plans, based on successful, conventional Lennar designs, are not bad, if you can accept the inevitable two car garage. At least it is not a snout sticking out; there is a bedroom at the front which can act as a home office. I like the rounded corners everywhere. (Take a 3D video tour here)

The ribbed walls are going to probably be an issue with dust collection, (and a greasy disaster behind the gas stove in the kitchen, which should NEVER have a combo microwave fan above, but that is another kvetch) but I like the look of them. The homes are apparently cheap to run; according to Construction Briefing,

“We got a utility bill from one of the customers there from last week,” said [ICON construction VP Spencer] Padgett. “For a 1,850 sq ft house, [the energy bill was] $35 for the entire month. It doesn’t rot, there’s no bugs that are going to eat it, it’s not effected by humidity,” continued Padgett, noting advantages. “The walls are just stronger.”

What’s not to love?

For one thing, it is a carbon bomb. The houses are in a car-dependent suburb of Austin, and being single family dwellings, have a lot more exterior wall. It is a system designed for sprawl, given the difficulty of doing second floors.

Then there is the concrete they are squirting out; as Brian Potter of Construction Physics noted,

“3D printable mixes differ from traditional concrete in that they have no large aggregate, only sand (making them more like grout than concrete). They also have very large fractions of cement or cementitious materials – they seem to hover around a ratio of 1:2 between cement and aggregate, compared to a 1:7 ratio for more traditional concrete.”

As I noted in my prior post, “The walls here are thinner than poured concrete, so there is less of it, but then they are pouring all the interior walls out of the stuff as well, and pound for pound, it is almost solid CO2.”

I am biased towards natural materials like wood and straw, but this is Texas. I prefer higher densities and multi-storey designs, but ICON is working on that too, with a new Phoenix printer that can reach up 27 feet and do roofs.

But I am not convinced that this can scale; those are expensive machines and they are not particularly fast, and there is something funny about the money, this is not the conventional development model.

While the Homes at Wolf Ranch have conventional plans in a subdivision, ICON is also working with Bjarke on a project in West Texas with wild plans that take advantage of the freedom that the printer allows, doing curvy forms “made possible by the capabilities of ICON’s 3D printing technology while adding strength and beauty to the overall structure.”

Here is why I am so conflicted. ICON and Bjarke are pushing the technological and design envelope. But these are big second homes made of concrete miles from anywhere, truly carbon H-bombs. The emissions from making the homes and driving to them directly contribute to climate change, and who knows if this part of Texas will even be habitable in a few years.

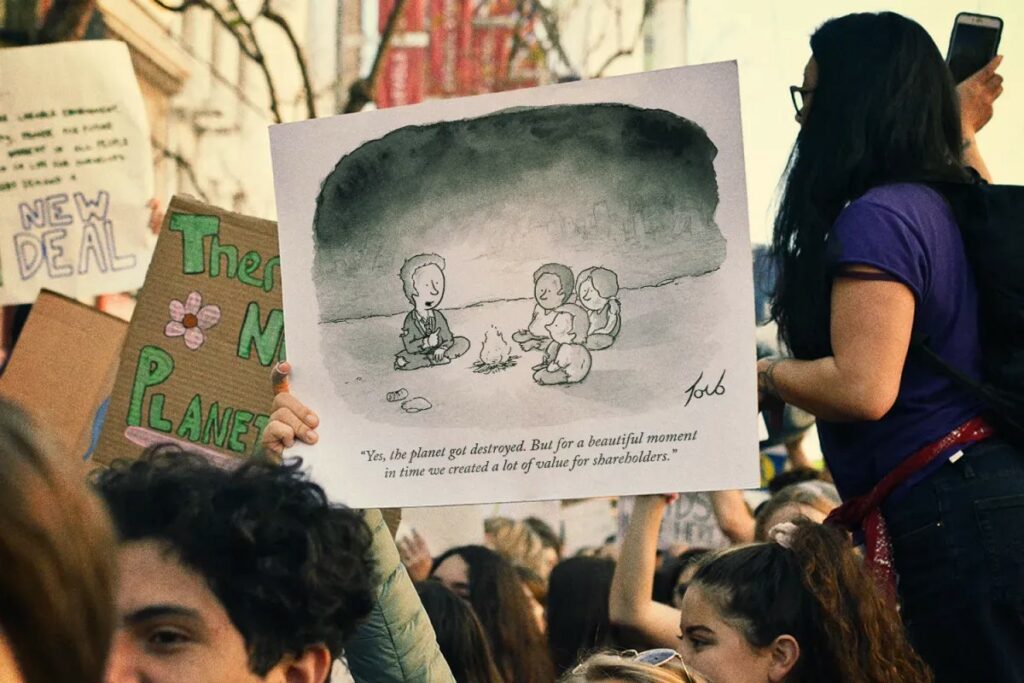

To paraphrase the great 2012 Tom Toro cartoon in the New Yorker,

“Yes, the planet got destroyed. But for a beautiful moment in time before it got too hot, we built some neat concrete houses in the desert and had some great parties.”